Unveiling the Art of Custom Screen Printing on Shirts

Custom screen printing on shirts is a popular method of apparel decoration, offering endless possibilities for creating unique designs with vibrant colors and crisp details. In this comprehensive guide, we will explore the intricate process of custom screen printing on shirts, from design conception to the final product. Whether you’re a seasoned printer or a novice enthusiast, understanding each step of the process is crucial to achieving high-quality results. Let’s dig into the interesting realm of custom screen printing on shirts.

- Design Preparation: The journey of custom screen printing begins with the design phase. Whether it’s a hand-drawn illustration or a digital graphic, the design must be meticulously crafted to ensure it translates effectively onto fabric. Designers consider factors such as color selection, layout, and scale to achieve the desired aesthetic. Once the design is finalized, it is separated into individual colors, with each color requiring its own screen for printing.

- Screen Preparation: Screens are the foundation of screen printing. Each color in the design corresponds to a separate screen, which is made by stretching a fine mesh over a frame. The stencil for each color is created on the screen using a light-sensitive emulsion. Once exposed to UV light, the emulsion hardens in the areas corresponding to the design, leaving behind a stencil on the screen.

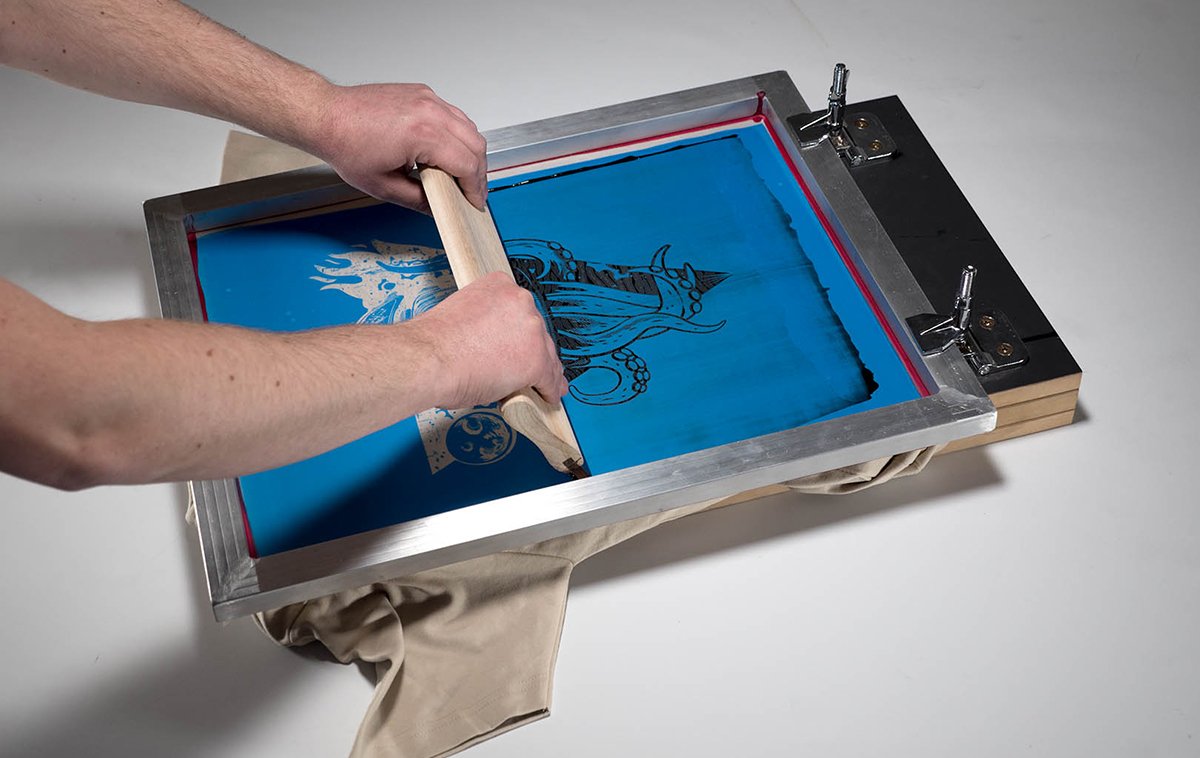

- Setting Up the Printing Press: With the screens prepared, the printing press is set up for production. The shirt is placed on a printing platen, which holds it securely in place during printing. The screens are aligned on top of the shirt in registration to ensure accurate placement of each color layer. Ink is applied to the screen, and a squeegee is used to evenly distribute the ink across the screen, forcing it through the mesh and onto the shirt below.

- Printing Process: With the setup complete, the printing process can commence. The squeegee is pulled across the screen, transferring the ink onto the shirt in the desired design. For multi-color prints, each color is printed sequentially, with the shirt passing through the printing station for each color layer. As each color is applied, the vibrant hues begin to emerge, bringing the design to life.

- Curing and Finishing: After printing, the shirts undergo a curing process to ensure that the ink bonds properly with the fabric and achieves maximum durability. This is typically achieved using a conveyor dryer, which applies heat to the printed area, curing the ink and ensuring that it withstands repeated washings and wear. Once cured, the shirts are inspected for quality, and any necessary touch-ups are made before they are ready for distribution or retail sale.

Conclusion:

Custom screen printing on shirts is a meticulous process that requires skill, precision, and attention to detail. By understanding each step of the process, individuals and businesses can create high-quality, customized shirts that showcase their creativity and style. With the right tools, techniques, and expertise, custom screen printing offers endless possibilities for creating eye-catching designs that make a statement on shirts and other apparel items.